In the ever-evolving landscape of safety standards within the climbing and adventure sports industry, the significance of high-performance matting has become increasingly apparent. In our previous article: “The Evolution of Climbing Mats”, we delved into the remarkable advancements that have shaped safety measures for bouldering and rope climbing. However, a fascinating aspect emerges when we consider the global perspective — the diversity of safety regulations and standards across different regions. This article will briefly touch upon and discuss key aspects of international safety standards, focusing specifically on bouldering.

Safety Matting Standards and Regulations

It is important to note, this article will only focus on best practices outlined by regions around the world with Safety Standards. Some countries such as New Zealand or the United States, have recommendations that refer to guidelines but no official safety standards that gyms must adhere to. The below table outlines the relevant Safety Matting Standards.

| Australian Standards | European Standards | Other Regions |

|---|---|---|

AS 2316.1.1-2021 | EN 12572-2:2017 | No Official Standards, Refer to: |

AS 2316.1.2-2021 | NE P90-311:2009 (France) | EN 12572, EN 1177, ASTM F355, Part E |

Australian Standards

At ICP, one of our foundational principles is that “Safety is a fundamental human right,” and we approach safety with utmost seriousness. In line with this commitment, ICP CEO Rob Parer actively participated on the advisory group to help shape the Australian safety regulations (AS 2316.1.1-2021 / AS 2316.1.2-2021), and was able to discuss with peers industry best practice. Similar to European standards, we assess the effectiveness of an impact on safety matting through via a series of Impact Attenuation Testing, also known as Accelerometer Drop Testing.

Specific metrics such as Head Injury Criteria (HIC), Maximum G-force, and Delta-t figures are meticulously recorded from a series of critical fall heights, adhering to the prescribed standards. To delve into specifics, the impact attenuation outcome of a particular safety matting is heavily influenced by the material, thickness, and stiffness of the matting. The resulting effectiveness of these factors determine how the matting will perform during an impact event and must comply with the Australian Safety Standards (Gmax less than 50g and the HIC to less than 200 with an impact event duration of greater than 12 ms). When you reach the limit of any one variable this will determine your fall height and set the maximum a users body may be off the Impact Attenuation System (IAS). A 4.6kg hemisphere indenter is used to calculate the critical fall height and simulate a the human head on the IAS during an impact event.

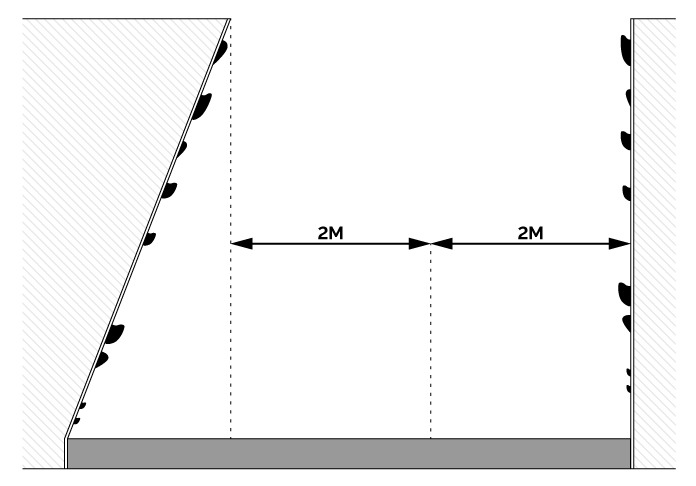

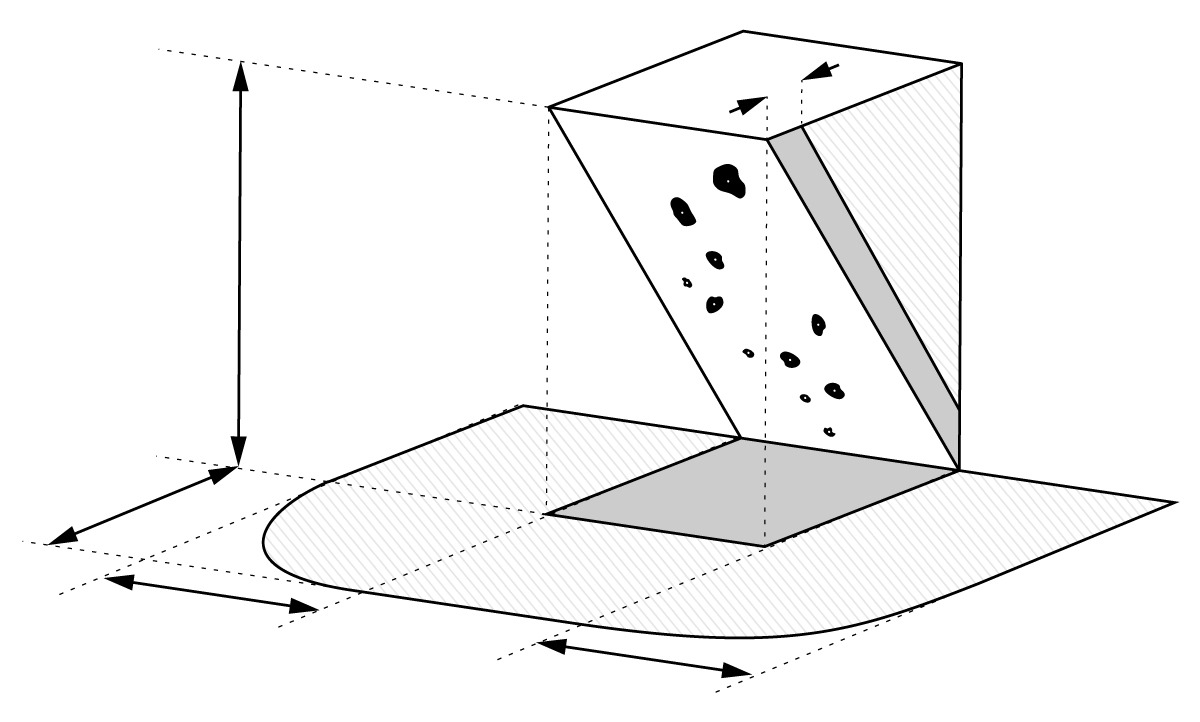

Another crucial facet of Australian Safety Standards for Climbing Mats involves considerations of the fall zone. Australian guidelines mandate a minimum 2m fall zone from the climbing wall’s most extreme point, with opposing walls avoiding overlapping fall zones (a minimum of 4m fall zone). At ICP, we typically exceed this requirement, extending the minimum fall zone radius to 2.5m to enhance safety and reduce the risk of climbers falling beyond the mat area and giving route setters a greater range of freedom in their setting styles.

The guidelines also stress the importance of elimination of potential entrapment or trip hazards within the matted area, addressing any gaps between the matting and the climbing wall.

European Standards

Europe stands out for its meticulous attention to safety standards and regulations, exemplified by the comprehensive EN 12572-2:2017. The continent’s rich climbing history, spanning both indoor and outdoor environments, likely plays a pivotal role in the implementation of stringent safety measures. An intriguing facet of Europe’s safety commitment lies in the existence of country-specific variations, exemplified by France’s NF P90-311:2009. This diversity across European regions fosters an environment conducive to shaping international safety standards. Emphasizing the significance of individual safety standards for each country’s climbing association or industry, it provides a valuable framework for cross-country comparison and enables nations without established standards to derive insights for formulating best practices. Comparable to Australia, European standards meticulously outline various components of safety matting, with three key elements standing out: Impact Attenuation Rating, Fall Zones, and Testing for IAS Joins and Gaps. Interestingly, each of these components differs from Australian standards in unique ways, prompting a closer examination of their distinct specifications.

When it comes to the impact attenuation capacity of foam safety mats in Europe, the crucial and regulated aspect is the shock absorption qualities of the matting. This is determined by three components outlined in the standards: Peak Deceleration, Deflection, and Resilience. Once again, the testing is conducted through drop testing within a laboratory setting, but this time a 30kg hemisphere indenter must be utilized. This may be used to simulate the impact to the entire body, as opposed to just the impact to the head as per the Australian Standards. When the test indenter or a climber impacts the mat, the peak deceleration refers to the moment when the climber’s speed decreases most rapidly upon hitting the mat; the Peak Deceleration must fall between ≥ 15 and ≤ 25. Deflection pertains to the extent to which the safety mat compresses or deforms when a force is applied, such as when a climber falls onto it. Following an impact, the deflection of the mat must be less than 80%. The resilience of a climbing safety mat is its ability to absorb impact energy during a fall and then return to its original shape (must be less than 15%). It’s important to note that these figures are for brand new matting, and the impact attenuation capacity of mats will decrease over time.

The fall zone regulations also differ to the Australian Standards, factoring in the height and orientation of the wall. For boulder walls with heights up to 3m, the European safety guidelines mandate a fall zone of 2.0m in front of the wall and half the wall’s height to the side. As for boulder walls ranging from 3.0m to the maximum 4.5m height, the minimal safety distances increase to 2.5m in the front and 1.5m on the side. It’s crucial to note that these are minimum fall zones outlined in the guidelines and do not eliminate all risks of injury. Conducting a thorough risk assessment at each new climbing facility is essential to identify potential areas of increased risk. ICP consistently recommends extending matting in fall zones with significantly overhung walls and towards the end of a climbing wall.

Similar to Australia, it is a common for regulations to stipulate the absence of gaps between the matting and between the matting and the climbing surface in order to mitigate the risk of limb entrapment and potential tripping hazards. However, European standards take an additional precautionary measure by necessitating the testing of IAS joins for both breaking force and cyclic tensile strength. This added requirement aims to prevent joins from breaking or slipping during impact events, thereby minimizing the likelihood of injuries stemming from such incidents.

Other Climbing Industries

Diverging from Australia and the European region, numerous regions and countries, with the United States being a notable example, have yet to adopt official safety standards. Over the years, the industry has engaged in an ongoing discourse on whether to establish these standards. This discussion arises from concerns about the global growth of the climbing industry, with apprehensions that new facilities might opt for minimal safety systems in the absence of official regulations. The debate has garnered perspectives from both sides, with some contending that existing gym owners may be hesitant to upgrade safety equipment, fearing the potential replacement of matting or climbing walls. On the contrary, proponents of standards argue that regulations would provide climbers with the assurance that the IAS installed for their protection undergo testing, adhere to regulations, and are deemed safe.

From the very beginning, one of ICP’s primary focuses has been on developing the most high-performing mats available in the market. We are consistently enhancing the safety capabilities of ICP Mats, encompassing the materials we employ, our innovative matting design, and even our IAS joining mechanism. Rigorous safety testing, including impact attenuation testing, has been conducted on ICP mats to showcase compliance with all prevailing international safety standards. This commitment guarantees the highest level of safety, risk mitigation, and confidence for both climbers and route setters.

While the safety standards for major regions worldwide exhibit numerous similarities, it is crucial to acknowledge the distinctive rules that each region maintains. When purchasing new safety matting it is not only important for the product to comply with these requirements but also cover the unique risks that are present in your venue. For further insights into these standards and detailed information on our accelerator drop testing results, we invite you to contact us and explore the comprehensive measures we undertake to uphold safety in climbing.